Resilient Manufacturing: Building Strength Amid Global Disruptions with AI, PLM and Flexible Operations

In this article, let’s take a look at How to build resilience in manufacturing with AI, PLM, and flexible operations to overcome global disruptions, tariffs and supply chain challenges.

Resilient Manufacturing: Building Strength Amid Global Disruptions

In an era once defined by seamless globalization and interconnected supply chains, the world today is witnessing a profound shift. Trade wars, tariffs, regional conflicts, and the resurgence of protectionist policies are reshaping global manufacturing dynamics.

The promise of efficiency and cost advantage through global integration is now being challenged by geopolitical volatility and anti-globalization trends.

Amidst this uncertainty, one idea is gaining strategic importance across boardrooms — Resilient Manufacturing.

It’s not just an operational philosophy; it’s an existential necessity. To thrive in the age of disruption, manufacturers must reimagine their systems, processes, and people to anticipate shocks, adapt swiftly, and sustain long-term competitiveness.

The Age of Anti-Globalization and Tariff Complexity

For decades, manufacturing thrived on the backbone of globalization. Companies distributed design, production, and assembly across continents to capitalize on lower costs and scale advantages. But this global web has begun to fray.

The new age of economic nationalism, tariff wars, and supply chain realignment is changing the rules. From U.S.–China tensions to the Russia–Ukraine conflict and shifting trade alliances, global interdependence has become a double-edged sword.

- Tariffs and import restrictions are increasing production costs and complexity.

- Supply chains are being disrupted by political sanctions and regional instabilities.

- Manufacturers are forced to localize production while maintaining global standards.

The result is a manufacturing world that can no longer depend solely on optimization—it must build resilience.

Why Manufacturing Resilience Must Be a Strategic Imperative

Resilience is more than risk management. It’s the ability of manufacturing ecosystems to absorb shocks, adapt dynamically, and recover stronger.

In practical terms, resilience ensures that production can continue—even when suppliers fail, markets shift, or global transport systems break down.

Three major forces demand this strategic pivot:

- Geopolitical Uncertainty – Nations are increasingly prioritizing domestic production and imposing export controls. Manufacturers dependent on single-country sourcing face existential threats.

- Environmental and Climate Risks – Floods, droughts, and energy crises disrupt factory operations and logistics, exposing the fragility of linear supply chains.

- Technological Disruption – Rapid AI-driven automation and digital transformation are redefining production models, requiring constant agility.

The Pillars of Resilient Manufacturing

Resilient manufacturing rests on three foundational pillars: Digital Integration (via PLM Systems), Human–Tech Symbiosis, and Operational Flexibility.

1. PLM Systems as the Digital Backbone

Product Lifecycle Management (PLM) systems have evolved from data repositories into strategic enablers of resilience. They unify design, engineering, procurement, and service data, enabling real-time decision-making during disruption.

How PLM Drives Resilience:

- Visibility: PLM provides a single source of truth for product and process data. In crises, it helps quickly identify which parts, materials, or suppliers are affected.

- Traceability: Every product component’s origin, certification, and compliance can be tracked—crucial when facing import/export restrictions or supplier replacements.

- Scenario Simulation: Integrated PLM systems can run “what-if” simulations—testing the impact of material shortages or design changes before they hit production.

- Collaboration Across Borders: Even if physical mobility is limited, cloud-based PLM platforms enable cross-functional collaboration between global teams in real time.

PLM thus acts as the nervous system of resilient enterprises—connecting every process, sensing risks early, and coordinating quick responses.

2. Human–Tech Symbiosis: The Core of Industry 5.0

While Industry 4.0 emphasized automation, Industry 5.0 focuses on collaboration between humans and intelligent systems. Resilience doesn’t come from technology alone—it comes from people who know how to use it intelligently.

Human-Tech Synergy in Action:

- AI-Augmented Decision-Making: Engineers can use AI and LLMs to evaluate supply chain alternatives, optimize design for local sourcing, and simulate production outcomes.

- Knowledge Retention: Human expertise combined with digital knowledge systems ensures that critical tribal knowledge doesn’t vanish during turnover or crisis.

- Empowered Workforce: A digitally fluent workforce can adapt operations rapidly—switching suppliers, adjusting designs, or modifying workflows without waiting for top-down decisions.

In a world of constant change, the resilience of an organization mirrors the adaptability of its people.

3. Flexible Operations and Distributed Manufacturing

The third pillar of resilience lies in flexible and distributed operations. Instead of concentrating production in one region, manufacturers must adopt multi-site and modular production strategies.

Resilience through Flexibility:

- Localized Manufacturing Hubs: Establishing micro-factories closer to customer markets reduces reliance on global shipping networks.

- Dynamic Supply Networks: AI can identify backup suppliers, evaluate capacity, and reroute orders in real time.

- Modular Product Designs: Designing components for interchangeability allows faster substitutions during supply chain disruptions.

By embracing flexibility, manufacturers transform uncertainty into opportunity.

Steps to Build Resilient Manufacturing in Industry 5.0

For manufacturers aiming to strengthen resilience, here’s a strategic roadmap:

Step 1: Conduct a Digital Resilience Audit

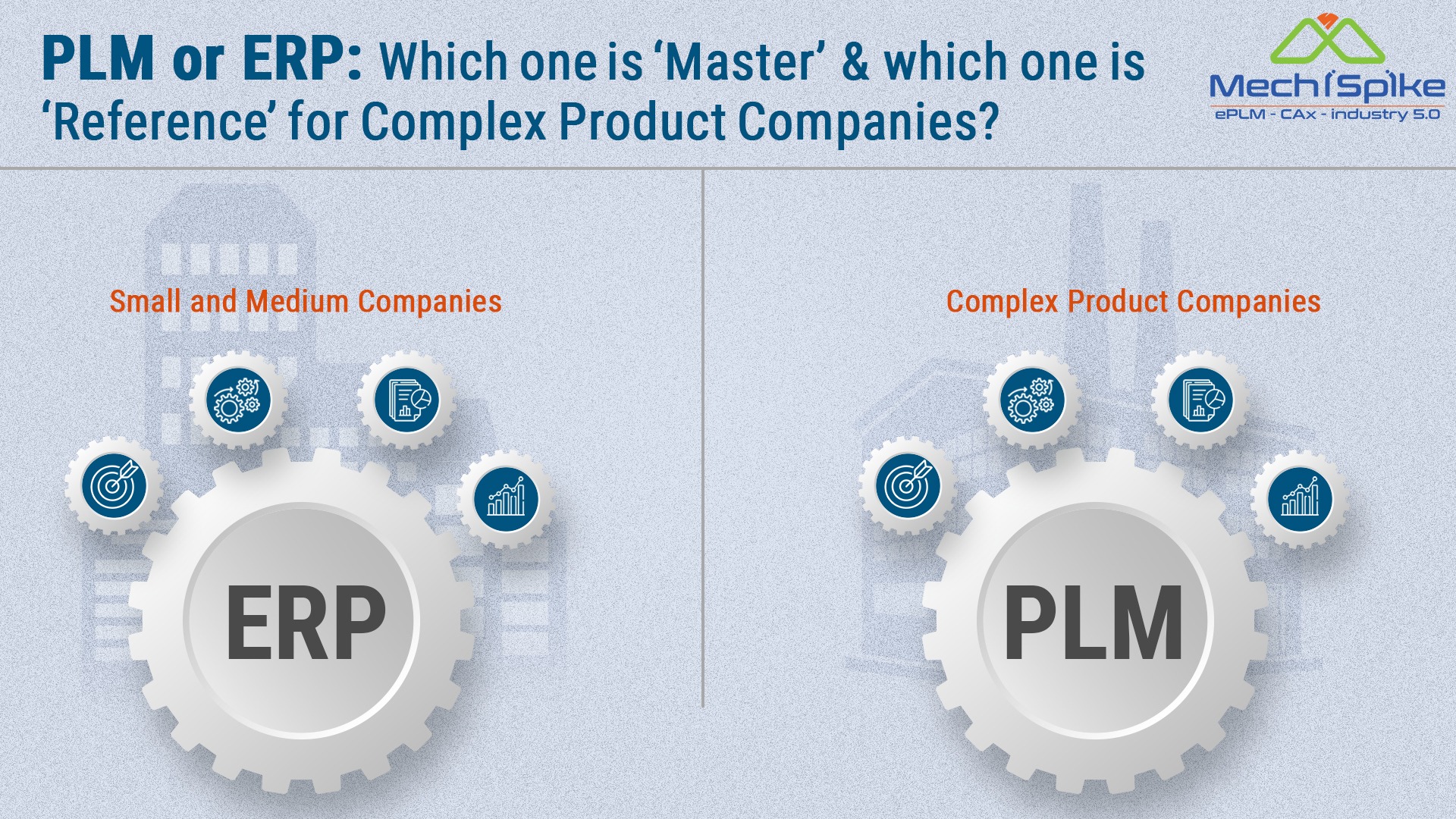

Assess how well your PLM, ERP, and supply chain systems handle disruptions. Identify data silos, outdated workflows, or manual dependencies.

Step 2: Map Supply Chain Dependencies

Visualize your global supply chain network and identify critical nodes. Use AI to model how tariff changes or geopolitical shifts impact cost and delivery.

Step 3: Invest in PLM-Driven Integration

Ensure that design, sourcing, and manufacturing data are unified through PLM systems. This integration allows for faster design modifications when material availability changes.

Step 4: Build Human–AI Collaboration Models

Train teams to use LLMs and predictive AI tools for decision support. Encourage “augmented intelligence” instead of full automation to retain human judgment.

Step 5: Redesign for Modularity and Sustainability

Adopt modular architectures that make parts interchangeable. Prioritize recyclable materials and energy-efficient processes to align resilience with sustainability.

Step 6: Develop Regional Manufacturing Networks

Diversify manufacturing and supplier bases across multiple regions to balance efficiency with resilience.

Step 7: Create a Crisis Response Framework

Define clear protocols for data access, communication, and decision-making during disruptions. Regularly run digital “war-room” simulations to test preparedness.

The Human Element: Skills for Resilient Manufacturing

Technology alone doesn’t make an organization resilient—people do. The Industry 5.0 workforce must combine technical expertise with agility, empathy, and foresight.

Key people skills include:

- Digital Literacy: Ability to work with PLM systems, data visualization tools, and AI-driven decision aids.

- Critical Thinking: Evaluating multiple disruption scenarios and selecting the best response path.

- Cross-Functional Collaboration: Working seamlessly across engineering, procurement, logistics, and sustainability functions.

- Change Agility: Rapidly adapting to new technologies, roles, and workflows as markets shift.

- Cultural Intelligence: Managing diverse, distributed teams with sensitivity to local regulations and cultural contexts.

- Sustainability Mindset: Viewing resilience and environmental responsibility as interconnected goals.

Conclusion: From Fragile to Flexible

The world is entering a phase where disruption is the new normal. Manufacturers can no longer depend on just-in-time efficiency—they must build just-in-case resilience.

Resilient manufacturing isn’t about avoiding disruption; it’s about thriving through it. It’s about integrating PLM systems for visibility, empowering humans with AI for smarter decisions, and building flexible networks that adapt to change.

As tariffs rise, global alliances shift, and environmental risks grow, resilience becomes not just an operational need but a strategic advantage.

The future belongs to manufacturers who treat resilience not as a cost—but as an investment in continuity, credibility, and competitiveness.

In Industry 5.0, resilient manufacturing is not just about making products—it’s about making progress that endures.

MechiSpike can be of great help here to take your organization to the future of Product Design as well as Manufacturing with our focus on Industry 5.0 using our prowess in PLM, Engineering and IT Digital.

Click here to know more about us.

For Corporates :

MechiSpike can be of great help to your organization to help you improve your PLM ROI and 30% Savings, be it the hiring cost in staffing or setting up an ODC.

We do this with efficient planning, organizing and controlling Product Master data with seamless data exchange among Engineering, Manufacturing and Enterprise systems.

With our well established niche expertise in PLM, we are now serving more than 15 Global Clients. They are now looking at us as a ‘Go To’ partner for Engineering, IT and PLM. With this confidence, we are expanding our scope of services beyond PLM to Industry 5.0 Digital Transformation i.e. PLM, ERP, CAD, Cloud, AI and DevOps.

Why MechiSpike :

RightSourcing is ‘Better Outsourcing’, given to ‘NICHE EXPERTS’.

Click here to know how we can actually help you with our Proven Methodologies.

For PLM Careers :

Learn More | Earn More | Grow More

Interactive UI : Every Application will get a response with a recruiter contact details and the applicant will get a notification at each phase until the applicant is positioned well with our 15+ global clients in India, USA & Germany.

Candidate Referral Program : Refer a candidate and earn INR 25,000.

Mechispike Solutions Pvt Ltd is a PLM focused company, having all kinds of PLM projects to enable employee career growth and add value to clients. We can position you better with our 15+ global clients in India, USA & Germany.

We believe in “Grow Together” and “Employee First” culture.

Dream more than a Job. Grow your PLM Career to the Fullest with MechiSpike

Click Here to explore our Job Openings.

Subscribe Now :

Our mission : To equip you with the knowledge and tools you need to drive value, streamline operations, and maximize return on investment from your PLM initiatives.

PLM ROI Newsletter will guide you through a comprehensive roadmap to help you unlock the full potential of your PLM investment.

We are committed to be your trusted source of knowledge and support throughout your PLM journey. Our team of experts and thought leaders will bring you actionable insights, best practices, case studies, and the latest trends in PLM.

Subscribe Now to get this weekly series delivered into your Inbox directly, as and when we publish it.

To your PLM success!

Warm regards,

Visit Us: www.mechispike.com

If you want to Grow your PLM Career to the Fullest, Click Here to explore our Job Openings.

For PLM Services : Click Here to Schedule a Call with us.