A Look Back at 2024: What Changed for PLM

As the global landscape of Product Lifecycle Management (PLM) continues to evolve, each passing year brings forth new challenges, innovations, and shifts in the way organizations manage their product development processes.

In 2024, PLM saw transformative changes driven by advancements in technology, sustainability goals, and shifting business dynamics.

Let’s dive into the significant changes that unfolded in the world of PLM in 2024 and explore what PLM executives should focus on in 2025 to improve their return on investment (ROI).

The Significant Changes in PLM in 2024

1. AI-Driven PLM Takes Center Stage

2024 marked a pivotal year for Artificial Intelligence (AI) in PLM. From generative design to predictive maintenance, AI-powered tools became integral to streamlining product development and optimizing operations. Advanced machine learning algorithms provided real-time insights into market trends, enabling companies to make faster and more informed decisions. Additionally, AI-driven automation reduced manual interventions, improving efficiency across the product lifecycle.

2. Cloud Adoption Becomes the Norm

While cloud-based PLM solutions had already gained traction in previous years, 2024 saw an accelerated shift toward cloud adoption. Organizations moved their legacy PLM systems to the cloud to enhance scalability, collaboration, and accessibility. Cloud-native PLM platforms offered seamless integration with other enterprise systems, fostering better data sharing across departments and geographies. This transition also addressed security concerns with enhanced encryption and compliance standards.

3. Focus on Sustainability

Sustainability became a central theme in PLM strategies in 2024. Governments and consumers demanded greater transparency in product design and manufacturing processes, pushing organizations to integrate sustainable practices into their PLM workflows. Lifecycle assessment tools within PLM systems helped evaluate the environmental impact of materials and processes, enabling companies to make eco-friendly decisions. Circular economy principles, such as design for reuse and recycling, were also embedded into PLM frameworks.

4. The Rise of Digital Twins

Digital twin technology gained significant momentum in 2024, revolutionizing the way products were designed, tested, and maintained. By creating virtual replicas of physical products, organizations could simulate performance, identify potential issues, and optimize designs before production. This not only reduced costs but also accelerated time-to-market. The integration of IoT data into digital twins provided real-time performance monitoring, enabling predictive maintenance and improved product reliability.

5. Enhanced Collaboration Across the Ecosystem

The importance of collaboration in PLM reached new heights in 2024. With supply chains becoming more complex and geographically dispersed, organizations embraced tools that facilitated better communication and data sharing among stakeholders. PLM platforms evolved to support seamless collaboration with suppliers, partners, and customers, ensuring all parties had access to up-to-date product data. This collaborative approach reduced errors, improved quality, and strengthened relationships across the ecosystem.

6. Integration with Industry 5.0

2024 saw PLM systems aligning more closely with Industry 5.0 initiatives. The integration of PLM with technologies such as IoT, robotics, and additive manufacturing enabled smarter and more efficient production processes. Real-time data from IoT sensors fed directly into PLM systems, creating a continuous feedback loop between product design and manufacturing. This integration allowed organizations to respond quickly to changes and optimize their operations.

7. Shift Toward Open Standards

As interoperability became a critical factor in PLM, 2024 witnessed a shift toward open standards. Companies demanded PLM solutions that could easily integrate with other enterprise systems, reducing vendor lock-in and fostering flexibility. Open standards facilitated seamless data exchange between PLM platforms and ERP, CAD, and MES systems, empowering organizations to build more robust and interconnected ecosystems.

8. Focus on User Experience (UX)

Recognizing that the adoption of PLM tools often hinged on user satisfaction, vendors prioritized improving the user experience in 2024. Simplified interfaces, intuitive workflows, and enhanced customization options made PLM systems more accessible to users across various roles. The focus on UX reduced training times, boosted adoption rates, and improved overall productivity.

9. Data-Driven Decision-Making

With the explosion of data generated across the product lifecycle, 2024 emphasized the need for advanced analytics in PLM. Business intelligence (BI) tools integrated into PLM systems allowed executives to extract actionable insights from vast datasets. From tracking product performance to analyzing customer feedback, data-driven decision-making empowered organizations to stay competitive in a dynamic market.

What PLM Executives Should Focus on in 2025

To capitalize on the advancements of 2024 and improve PLM ROI, executives should prioritize the following strategies:

1. Embrace Continuous Innovation

Stay ahead of the curve by adopting emerging technologies and best practices. Evaluate AI, digital twins, and Industry 4.0 technologies to identify opportunities for innovation within your PLM processes.

2. Invest in Talent and Training

Empower your workforce with the skills needed to maximize the potential of modern PLM tools. Provide regular training sessions and foster a culture of continuous learning to drive adoption and efficiency.

3. Focus on Sustainability Metrics

Integrate sustainability metrics into your PLM workflows and set measurable goals. Use lifecycle assessment tools to track progress and demonstrate your commitment to environmental responsibility.

4. Enhance Collaboration

Leverage cloud-based PLM solutions and advanced collaboration tools to foster seamless communication among all stakeholders. Strengthen partnerships with suppliers and customers by ensuring transparency and accessibility of product data.

5. Prioritize Data Security

As reliance on digital platforms grows, ensuring robust data security measures is critical. Invest in advanced encryption technologies and comply with global data protection regulations to safeguard sensitive information.

6. Leverage Analytics for Strategic Insights

Use advanced analytics and BI tools to monitor key performance indicators (KPIs) across the product lifecycle. Make data-driven decisions to improve product quality, reduce costs, and enhance customer satisfaction.

7. Adopt Agile PLM Practices

Transition from rigid workflows to agile PLM practices that enable flexibility and faster decision-making. Encourage cross-functional teams to collaborate on iterative product development cycles.

8. Build Resilience into PLM Systems

Prepare for disruptions by building resilience into your PLM systems. Ensure your platforms can adapt to changing market dynamics, supply chain challenges, and technological advancements.

Conclusion

The year 2024 was transformative for the PLM industry, with advancements in AI, cloud adoption, sustainability, and collaboration reshaping the way organizations manage their product lifecycles.

As we look ahead to 2025, PLM executives must focus on leveraging these innovations while addressing emerging challenges to maximize ROI.

By embracing continuous innovation, investing in talent, and prioritizing sustainability and analytics, organizations can unlock the full potential of PLM and drive long-term success in an increasingly competitive landscape.

MechiSpike can be of great help to Revolutionize Your Product Lifecycle with Industry 5.0 in 2025. With our Tailored PLM, Engineering & IT Solutions you can improve your PLM ROI starting 2025.

For Corporates :

MechiSpike can be of great help to your organization to help you improve your PLM ROI and 30% Savings, be it the hiring cost in staffing or setting up an ODC.

We do this with efficient planning, organizing and controlling Product Master data with seamless data exchange among Engineering, Manufacturing and Enterprise systems.

Why MechiSpike :

Niche Expertise in Engineering & IT

Our Speed of Hiring, Cost Optimized Solutions and Global Presence.

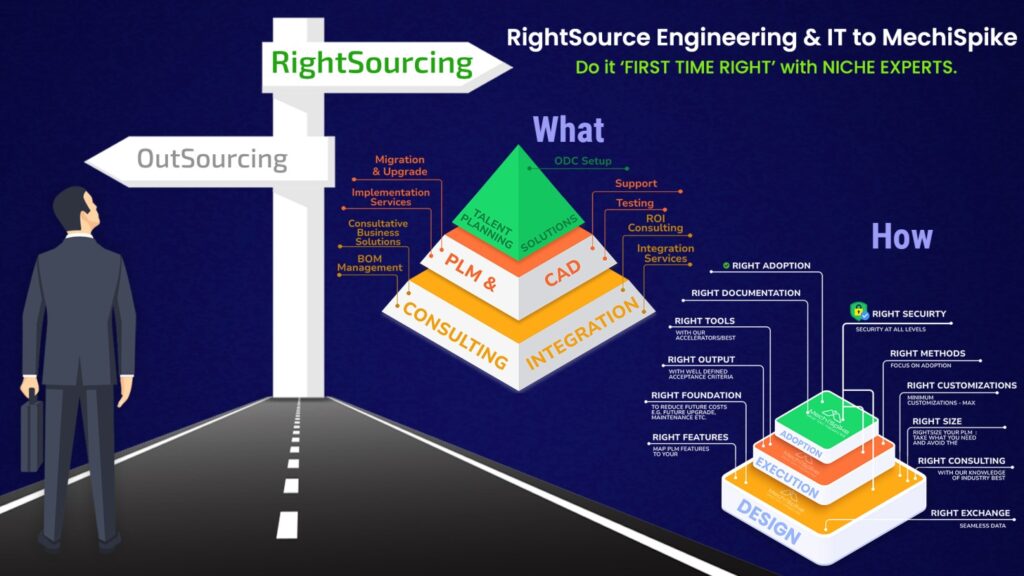

RightSourcing is ‘Better Outsourcing’, given to ‘NICHE EXPERTS’.

Click here to know how we can actually help you with our Proven Methodologies.

For PLM Careers :

Learn More | Earn More | Grow More

Interactive UI : Every Application will get a response with a recruiter contact details and the applicant will get a notification at each phase until the applicant is positioned well with our 15+ global clients in India, USA & Germany.

Candidate Referral Program : Refer a candidate and earn INR 25,000.

Mechispike Solutions Pvt Ltd is a PLM focused company, having all kinds of PLM projects to enable employee career growth and add value to clients. We can position you better with our 15+ global clients in India, USA & Germany.

We believe in “Grow Together” and “Employee First” culture.

Dream more than a Job. Grow your PLM Career to the Fullest with MechiSpike

Click Here to explore our Job Openings.

Subscribe Now :

Our mission : To equip you with the knowledge and tools you need to drive value, streamline operations, and maximize return on investment from your PLM initiatives.

PLM ROI Newsletter will guide you through a comprehensive roadmap to help you unlock the full potential of your PLM investment.

We are committed to be your trusted source of knowledge and support throughout your PLM journey. Our team of experts and thought leaders will bring you actionable insights, best practices, case studies, and the latest trends in PLM.

Subscribe Now to get this weekly series delivered into your Inbox directly, as and when we publish it.

To your PLM success!

Warm regards,

Visit Us: www.mechispike.com